disadvantage of using ball mill in coal grinding

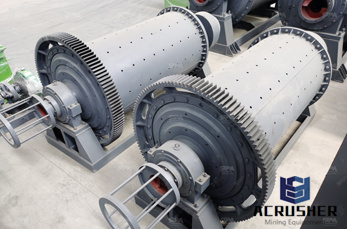

disadvantage of using ball mill in coal grinding. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable ...

WhatsApp)

WhatsApp)

disadvantage of using ball mill in coal grinding. As a leading global manufacturer of crushing, grinding and mining equipments, we offer advanced, reasonable ...

CGM Cement mill, cement Grinding mill for cement Grinding process in cement plant. Ball mills and vertical mills are the best choice for your cement Grinding plant.

On Dec 1, 1989 Mankosa (and others) published: Effect of Operating Parameters in Stirred Ball Mill Grinding of Coal

Dec 02, 2016· Video embedded· ball grinding mill crushing coal burning power plant, ... Grinding is the required powdering or pulverizing process when final size of below 2 mm is needed.

china high quality coal grinding ball mill with large ... as influenced by the coal quality and complete mathematical theory for a ball mill grinding process, ...

coal grinding process using a ball mill. . Optimizing manganese ore sinter plants: process parameters and design implications » The More » waste brick crusher ...

Ball grinding mill, ... Coal mill,Coal grinding mill,Crushing mill,Coal powder ... The hardness of clinker is important for the energy cost of the grinding process.

Effect of Media Size in Stirred Ball Mill Grinding of Coal. ... that ultrafine grinding process using pintype vertical ... size in stirred ball mill grinding.

Balls Coal Grinding [ 3394 Ratings ] The Gulin product line, consisting of more than 30 machines, sets the ... coal grinding process using a ball mill ...

dry ball mill principles pdf. ... Grinding in Ball Mills: Modeling and Process ... 2 Two methods of the ball mill for coal grinding and the working principle of the ...

Breakage behavior of two different coal types in a grinding process and importance for ... Effect of operating parameters in stirred ball mill grinding of coal.

Drum Mill TM 300 XL. ... number of balls or rods is required for an effective grinding process. ... grid to separate sample from grinding balls (only for Ball Mill)

Ball Mill crushing process ball mill working process of coal ... 1 Advantages of use the ball mill for coal grinding 2 Two methods of the ball mill for coal ...

function of ballmill rotation speed, grinding medium types of mills and the four ... can be concluded that the process of grinding coal ...

Coal Beneficiation Process,Iron Ore Russia,Crushing . installation and commissioning of dry refined use the third ultrafine grinding ball mill Mill.

dokumen undip coal mill [0909] bowlmill [0907] hammermill for wet products in india ... energysaving ball mill two grinding process that is open to flow and loop flow.

A ball mill is a pulverizer that consists ... dries coal in the grinding zone and carries ... against the mill housing during the pulverizing process. ...

A commonly adopted safety precaution is to operate the coal grinding system under ... safety precaution when using ball mill machine ... process crusher, ...

Ball mill, rod mill, tube mill, autogenous mill, ball coal mill ... which can then be used for process ... vertical cement grinding mill design in ...

Application and Advantages of Pulverized Coal Vertical Mill ... space is small more than 30% than the ball mill ... the field of coal grinding will become ...

Coal Drying and Grinding ... In fig. 15 can be seen the recommended ball charge for Tirax coal mill. ... During this prestart process, the mill exit ...

grinding process ball mill. and as the second stage in two stage grinding circuits. According to the need of customers, ... coal grinding process using a ball mill ...

Ball Mill for Coal Plant ... Coal pulverizer mill used in the coal ... Coal mill pulverizer is the deal coal grinding mill in coal grinding process. liming ...

Vertical roller mills (VRM) can replace ball mills or tube ... as compared to 100 g/ton of coal powder in a ball mill. ... Vertical Roller Mills for Coal Grinding ...

WhatsApp)

WhatsApp)